Case Studies and Technical Articles

How have other companies — including Fortune 500 brands — used Rotex Group industrial screeners?

Higher Capacities Shouldn’t Result in Good Wood Fibre Loss

Rotex Group’s wood fiber screening innovation keeps up with capacity increases without sacrificing performance and efficiency.

Click here to download this wood fiber loss prevention case study as a PDF.

Good pulp material in a fines bunker in a Scandinavian sawmill for wood fibre screening.

Wood Fiber Loss Problem

The development of new and revamped sawmilling lines using advanced saw blade and profiling technologies allows higher log feeding speeds that create larger volumes of wood chips with greater percentages of fines in the bi-product handling system.

Current Wood Fiber Screening Situation

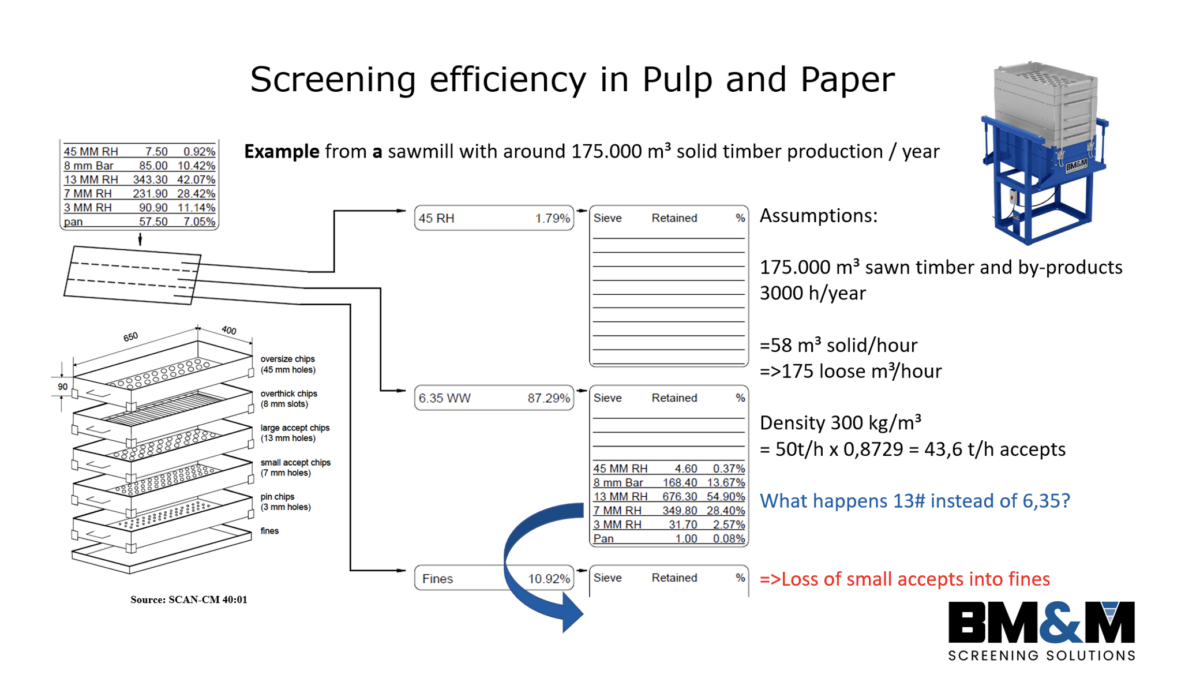

Current industry-wide screening technology did not innovate to address the higher volumes of fines. Instead of designing larger and more efficient screening machines, manufacturers of screening equipment forced sawmills to enlarge their screen apertures to keep a good, sellable pulp chip independent of and regardless to the losses being created in their screening machines’ fines fraction. To get the wood chips in spec, producers would open up the bottom fines deck from 8mm up to 10 or even 13mm to achieve less fines in the accepts but resulted in more acceptable material slipping into the fines bunker.

A modern Rotex Group Counterflow Chip Screen used in a wood chip screening application.

Wood Fiber Loss Prevention Solution

The Rotex Group brand offers technology with higher speeds and larger machine sizes to accommodate today’s modern saws and profiling lines. First, higher speeds in a true gyratory motion induce more energy into the screen, thus keeping the necessary smaller hole sizes from plugging. Secondarily, due to the balanced design of Rotex Group machines, brand engineers are able to design larger screening decks capable of handling the larger volumes generated by modern saw lines. The combination of larger single machines capable of maintaining pulp chip quality without sacrificing screening efficiency provides the right tool to satisfy the current industry’s needs.

Click here to download Rotex Group’s Counterflow CS Model wood chip screener spec PDF.

Wood Chip Screening Tools

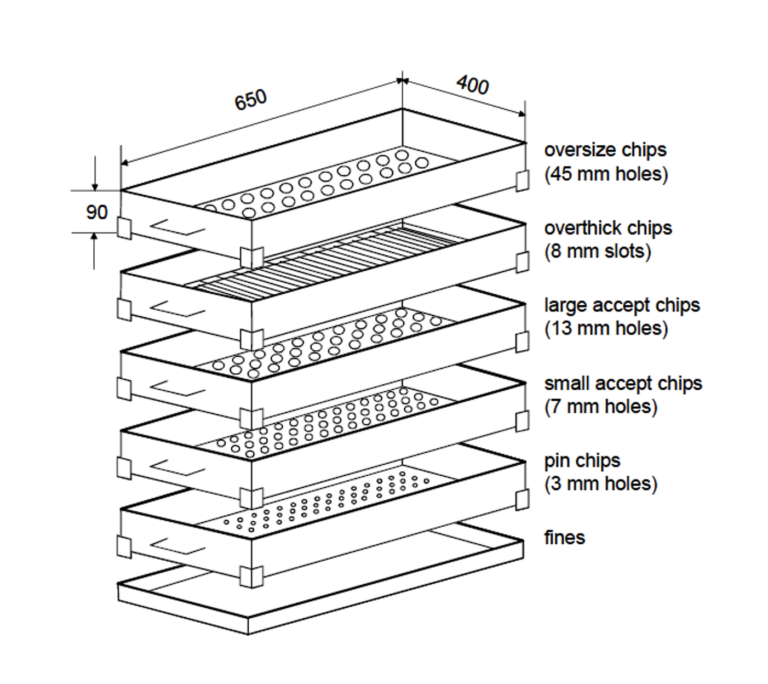

The development of new and revamped sawmilling lines using advanced saw blade and profiling technologies allows higher log feeding speeds. For an efficient screening solution, the screen sizes must be selected based on the fines content of the infeed material. Utilizing Rotex Group’s Chip Classifier, which mimics the same gyratory motion of production machines, engineers are able to lab test customers’ material to determine the optimal stroke length, speed, screen area, and screen sizes to maximize good wood fiber recovery. Typically, 6.35mm woven wire mesh is used to achieve the best results according to material loss. According to the SCAN Norm, larger holes mean users are wasting a fraction of small accepts, like shown in the figure below.

Rotex Group Chip Classifier using SCAN standard trays.

Classification of accepts according to SCAN (Source, Scandinavian Pulp, Paper and Board Testing Committee).

Summary: Screening Efficiency in Pulp and Paper

Rotex Group CS Model, a high-speed, high-volume gyratory screener designed for maximum efficiency.

Conclusion: Rotex Group innovation keeps up with capacity increases without sacrificing efficiency.

By tailoring screen sizes in accordance with customers’ specific wood fiber composition, followed by determining the right stroke length, speed, screen area and degree of incline, brand engineers are able to provide the optimal screening solution to meet today’s customers’ residual wood fiber composition, resulting maximum recovery of saleable product.