Classic Screen/Chip Screen

High-Capacity Industrial & Chip Screener Proven for Grain, Rubber, Forest Products, and More

Maximize your screening capacity without compromising on quality with the BM&M Classic Screen/Chip Screen gyratory screener. The Rotex Group’s BM&M brand has built high-efficiency screens since 1968. This is our highest energy, high-speed gyratory model, perfect for large volume applications across the wood chip, forest, paper, and general industrial sectors. The unique gyratory motion ensures maximum yield in a highly efficient process, eliminating blinding and reducing ongoing maintenance costs. Discover how the Classic Screen improves efficiencies and ensures maximum performance for virtually any application.

Request your custom screening solution and free materials testing below.

Why the Classic Screen is the Industry Leader

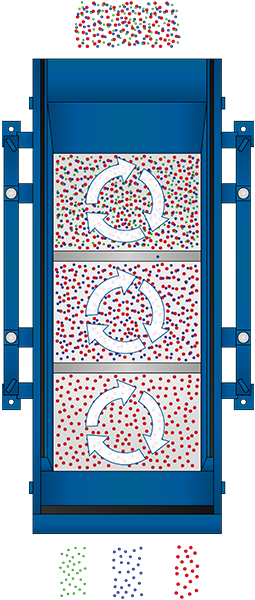

The Science Behind BM&M Gyratory Motion

This unique centered, high-speed gyratory motion applies higher G-force to the material bed, which eliminates blinding, maximizes throughput, and improves product quality. There are three core elements that work together to deliver these results:

- Centering the drive in the middle of the machine to generate the a gyratory motion over the entire screen surface.

- The eccentric weight drive assembly is lubricated for life. The unique static shaft design provides torsional stiffness ensuring long trouble-free service reducing ongoing machine maintenance costs.

- Increasing speed results in higher screening energy being applied to the material, eliminating blinding while also increasing throughput.

Key Benefits & Features of the Classic Screen/Chip Screen

Maximize Throughput with High-Capacity Gyratory Screening

Achieve maximum screening capacity without compromising on quality. The Classic Screen is our highest energy, high-speed gyratory model, perfect for large volume applications across the wood chip, forest, paper, and general industrial sectors. This ensures your operations run efficiently, improving overall productivity.

Superior Efficiency & Accurate Chip Classification

The unique BM&M fully gyratory motion ensures maximum yield in a highly efficient process. This superior stratification provides accurate chip length and thickness classification, which is crucial for maximizing valuable pulp fiber yield and minimizing fines, ensuring premium product quality.

Eliminate Blinding: Process Wet & Green Chips Effortlessly

Say goodbye to blinding and clogging. The aggressive, high-speed gyratory action prevents material from sticking to the screen mesh. With optional high-force ball decks, even challenging materials like wet/green chips, mulch, or rubber are processed without downtime for cleaning. Click here to watch a video of the Classic Screen used rubber recycling.

Reduce Costs with a Maintenance-Free & Reliable Design

Benefit from long-term reliability and lower operational expenses. The eccentric weight drive assembly is lubricated for life, ensuring trouble-free service. The robust, static shaft design reduces ongoing machine maintenance costs, providing a superior return on investment.

Rugged Construction for Demanding Industrial Use

Engineered for durability, the Classic Chip Screen features heavy-duty, stress-relieved welded construction designed to withstand the toughest industrial environments. This ensures a long typical lifespan and reliable performance year after year. Click here to watch a video of the Classic Screen used in charcoal screening.

Rugged Construction for Demanding Industrial Use

While a leader in wood and paper, the Classic Screen is also effective for screening a wide range of materials. Its adaptable design and custom configuration options make it ideal for screening wood chips, paper products, grain, mulch, rubber, and much more. Click here to watch a video of the Classic Screen used in almond screening.

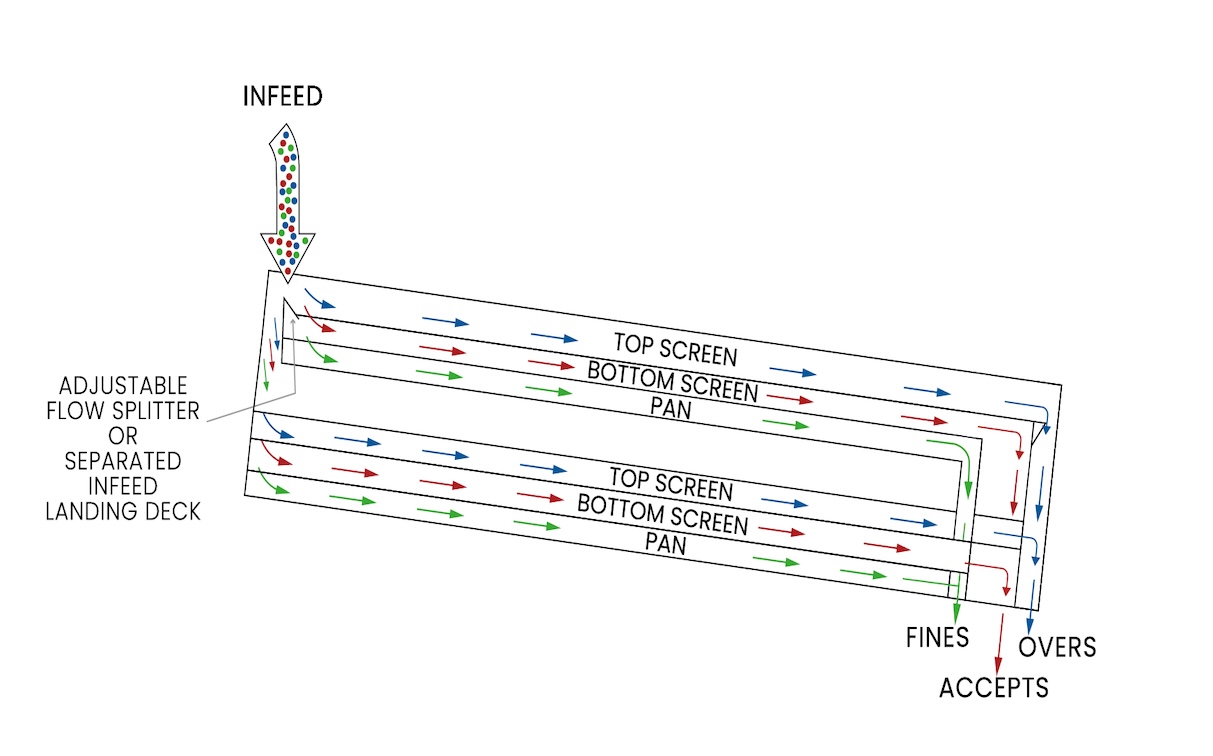

CS²: Efficiency Multiplied, Innovation Amplified

Largest Capacity, High-Speed Gyratory Screen

Experience the power of the Classic, squared, with the CS² model, our largest capacity, high-speed gyratory screen, perfect for large volume applications. Click here to watch a video of the CS² model.

Maximum Throughput Across Applications

This configuration is designed for maximum throughput in the wood, forest, and paper industries, as well as heavy industrial sectors like grain and rubber processing.

Product Options

Hanger Sling Assembly

Additional Support Option available to ensure no damage to your equipment in the event of double hanger failures.

Centralized Lubrication System

System designed to allow for greasing of the U-Joints by an operator without requiring a machine shut down period.

Over Travel Sensor

To detect when equipment is traveling outside the programmed range of motion and implement machine shutdown.

Upgraded Material for Wear Parts

A wide range of material upgrades can be provided to ensure your common wear components have a longer life span.

Zero Speed Switch

To detect when the machine has its regular operation disrupted or has reached a zero speed state.

Open Bottom Construction

Elimination of fines pan to eradicate blinding of fines material that can freeze or bond to metal in changing weather conditions.

Installation

BM&M Supplied Stand

The machine can be floor-mounted using a support stand designed for the specific machine.

Existing Structure

Because the machine suspension system has low to no vibration, the machine can be mounted directly to a structural steel framework using custom-length hangers assemblies.

Manual Request

Need an original manual to know what parts are needed for your BM&M equipment? Request one here and we’ll advise if it’s available.

* Required Field