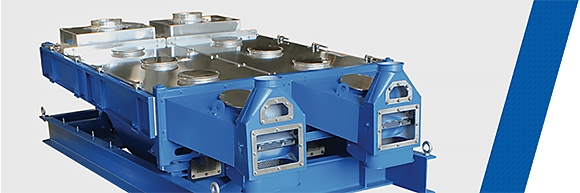

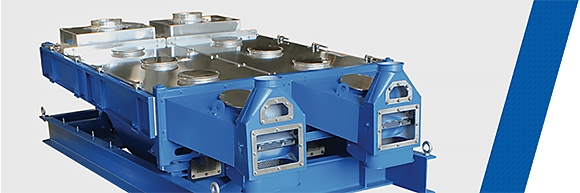

Apex Industrial Separators

Maximum efficiency. Minimal downtime.

The APEX™ industrial screener and separator provides extremely precise separations due to its Gyratory Reciprocating Motion. Its sleek, ergonomic, and lightweight design eliminates the need for multi-person maintenance crews and overhead hoists. The enabling of a one-person inspection and maintenance provides the same great Rotex efficiency at a lower operating cost.

In addition to improving the product quality, the storage and handling of the machine is improved with less troublesome foreign material to clog or contaminate the surrounding environment. The pretensioned screen panels, side mounted access doors, and easy access connecting sleeves located at the discharge end help increase plant safety while decreasing downtime.

Features

How It Works

Gyratory Reciprocating Motion

The Gyratory Reciprocating Motion gradually transitions along the length of the machine, starting off as purely gyratory motion at the head, then moving to elliptical movement in the center and reverting back to reciprocating toward the end.

- Circular motion at feed end

- Spreads the material across the full width of the screen surface

- Stratifies the material

- Aggressively conveys material forward

- Changing to elliptical motion at center

- Long-stroke elliptical action

- Enhances product stratification

- Conveys material at high capacity

- Reciprocating motion at discharge end

- Removes near-size particles

- Improves screening efficiency

- No vertical component ensures material is in constant contact with the screen surface

Benefits

Quick Screen Changes

Side access doors combined with pre-tensioned screen panels allow a single operator to change the entire machine in minutes.

More Uptime, More Profit

Easy single-operator inspection and maintenance results in increased processing uptime, reduced screening costs and the ability to produce more quality product.

Increased Screening Performance

When compared to standard separators, all Rotex machines deliver greater efficiencies, superior particle accuracies and higher yields.

Longevity and Durability

Rotex drives are designed for long-term, trouble-free service with minimal maintenance required.

Customisable

Ask your Rotex Group representative how we can fully customise your machine inlets/outlets and add liners, decks, aspiration and more.

Product Options

Aspiration

Most Rotex Group APEX Screeners can be equipped with aspiration hoods to remove dust and other light material. These hoods allow air to be pulled over the falling product stream and are adjustable for various products and rates. The aspiration feature efficiently removes unwanted, lightweight particles from the product stream. In addition to improving the product quality, the storage and handling of the product is improved with less troublesome foreign material to clog or contaminate the surrounding environment.

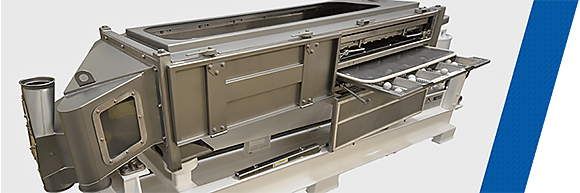

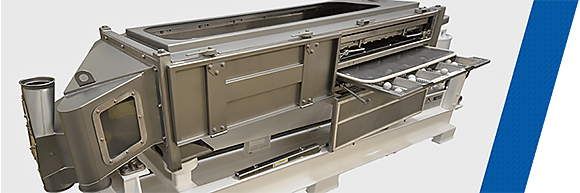

Cleanable APEX

The innovation of the Toolless Cam allows for positioning of the ball tray without a wrench, saving valuable time removing screens or ball trays for inspection or maintenance. This enables a single operator to complete all screen inspections quickly and easily, and offers many additional benefits such as uniform sealing pressure so that the screen panels are properly sealed every time. Toolless Cams can also be retrofitted to your existing Rotex Group APEX screener.

Specifications

Installation

Floor Mounting

Because the Rotex counterbalanced drive has low transmitted forces, the APEX can be floor-mounted in properly designed structures, a design feature unique to this type of equipment. The industrial screener can be mounted directly on the floor or on an elevated structural steel framework, which allows for drums and other equipment to be located under the machine. Rotex application engineers are available to recommend a stand for any specific application.

Cable Suspension

APEX screeners can be cable-suspended from the four corners of the machine, thereby isolating screening forces from the surrounding structure. Accurate counterbalancing of the APEX makes this type of installation option possible. If the existing overhead structure is not suitable or structurally unable to support the cable-suspended unit, the screener can be suspended from a floor-mounted cable support stand. As with conventional cable suspension, this option effectively isolates the horizontal out-of-balance screening forces, which minimizes costs for new structures and permits the use of older structures that might not otherwise support cable-suspended equipment. Note that certain Rotex Group APEX models can only be cable suspended.

Manual Request

Need an original manual to know what parts are needed for your Rotex equipment? Request one here and we’ll advise if it’s available.

* Required Field