CounterFlow CS Model

More volume in a smaller footprint.

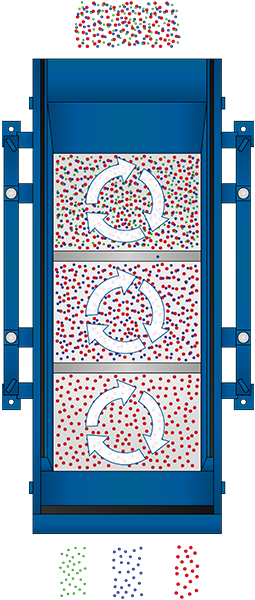

The CounterFlow CS Model is a unique concept that provides a tremendously efficient screen in a relatively small footprint. The double-length design is the key to its outstanding chip screening performance.

In the two-level design, the upper layer screens the material once and, from an elbow where the two levels meet, feeds the filtered material to the lower screen, where it is filtered again. Both screens move simultaneously, powered by a single gyratory motor.

BM&M Screening Solutions has been building impactful CS Model industrial screeners since 1987. Our CounterFlow CS Model allows you to double the screening area and increase efficiency over standard chip screening systems, without compromising performance or increasing maintenance costs.

Need more info on the CounterFlow CS Model industrial screener?

Features

BM&M Gyratory Motion

The unique technology developed by BM&M creates an unbeatable combination of motion and speed that generates higher throughputs and greater efficiencies. There are 3 core elements that work together to deliver these results.

- Centering the drive in the middle of the machine to generate a gyratory motion over the entire screen surface.

- The eccentric weight drive assembly is lubricated for life. The unique static shaft design provides torsional stiffness ensuring long trouble-free service reducing ongoing machine maintenance costs.

- Increasing speed results in higher screening energy being applied to the material, eliminating blinding while also increasing throughput.

Benefits

Double the Volume in the Same Footprint of Other Traditional Machines

Tight plant configuration? BM&M has you covered with the Counterflow CS Model design. Produce higher throughput than traditional designs with our multi-tiered design.

Lubricated for Life Drive System

BM&M’s drive can operate maintenance-free for 100,000 hours of service. All machines also include a 3 year drive warranty.

Higher Volume, Same Efficiency

BM&M has the highest G-Force for any gyratory screener that allows for a more efficient separation at higher capacities.

Quality Built for a Long Life

Our machines are manufactured in-house. BM&M machines are still running from the 1980’s and this is a testament to our superior quality workmanship.

Dynamic Adjustability to Meet Customer's Changing Needs

All BM&M machines can be easily modified at site for speed and stroke to meet customers’ changes in product specifications.

Eliminate Blinding

BM&M’s speed and stroke generate a higher G-Force resulting in a stronger horizontal acceleration that effectively eliminates blinding. Ball Decks are included as standard options with the Superscreen. The motion of the screen will propel the captive balls to strike the underside of the screen element and dislodge particles.

Product Options

Hanger Sling Assembly

Additional Support Option available to ensure no damage to your equipment in the event of double hanger failures.

Centralized Lubrication System

System designed to allow for greasing of the U-Joints by an operator without requiring a machine shut down period.

Over Travel Sensor

To detect when equipment is traveling outside the programmed range of motion and implement machine shutdown.

Upgraded Material for Wear Parts

A wide range of material upgrades can be provided to ensure your common wear components have a longer life span.

Zero Speed Switch

To detect when the machine has its regular operation disrupted or has reached a zero speed state.

Open Bottom Construction

Elimination of fines pan to eradicate blinding of fines material that can freeze or bond to metal in changing weather conditions.

Installation

BM&M Supplied Stand

The machine can be floor-mounted using a support stand designed for the specific machine.

Existing Structure

Because the machine suspension system has low to no vibration, the machine can be mounted directly to a structural steel framework using custom-length hangers assemblies.

Manual Request

Need an original manual to know what parts are needed for your BM&M equipment? Request one here and we’ll advise if it’s available.

* Required Field