Case Studies and Technical Articles

How have other companies — including Fortune 500 brands — used Rotex Group industrial screeners?

Plant-based Protein Production Using Hillenbrand Equipment

Hillenbrand’s commitment to sustainability supports plant-based protein production.

Rotex Group is passionate about our mission to Improve Lives Through Optimizing the Use of our World’s Natural Resources. Check out this article where our President, Lawrence Rentz, walks through how Hillenbrand equipment supports plant-based protein production:

Click here to download this article as a PDF.

Five years ago, following a holiday dinner, my wife decided that she was becoming a vegetarian. This was a big lifestyle change, and I wondered if it was just a fad. However, time went on and the change stayed. I started to understand and appreciate the concept, particularly because I had been watching Rotex Group increasingly engage with its customers through the lens of sustainable food innovation as the demand for food continues to grow.

The UN projects that the global population will increase 50% from 2000 to 2050.1 With rising incomes and increasing urbanization around the world, even the types of food that are in demand are changing: namely, demand for meat is projected to double by 2050.1 This growth raises serious sustainability concerns. Not only does raising livestock contribute significantly to the greenhouse gas (GHG) effect – livestock represent 14.5% of all human-caused GHG emissions2– but it also requires large amounts of land and generates massive amounts of waste, which can result in increased deforestation and water pollution.1

Click here to learn more about Rotex Group’s food separation and production capabilities.

This begs the question: how do we meet the growing demand for protein without further jeopardizing the environment and the well-being of future generations? A solution, one which is growing in scope and popularity, is to draw more protein from plant-based sources. Plant-based products have been ranked one of New Nutrition Business’s “Ten Key Trends in Food” since 2014, moving into the top three as of 2020.3 Plant-based proteins typically involve less energy, fewer resources, and less emissions than their meat counterparts which has led to an additional value-add to consumers wanting to explore adding plant-based protein to their diets for both environmental and ethical concerns. 1,5

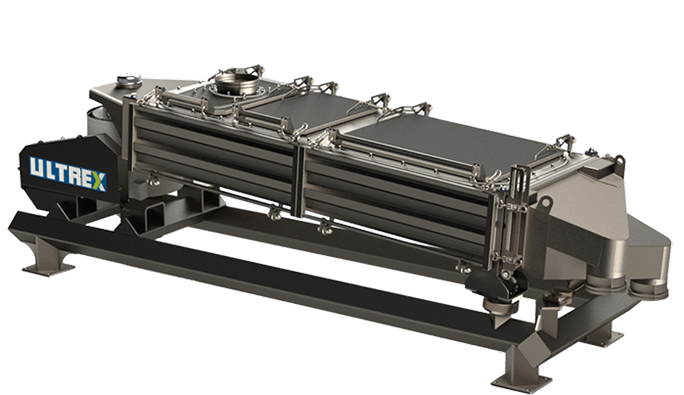

The ULTREX™ sanitary screener’s ergonomic design enables precise separations with one-person maintenance. And, ULTREX is USDA, EHEDG, and FSMA compliant.

How do companies in the Hillenbrand enterprise support the production of plant-based protein?

At Rotex Group, we design and sell industrial screeners that are used in the production of products such as pea starch and pea protein. Pea starches and proteins are key ingredients in many plant-based products, including plant-based burgers, noodles, non-dairy ice cream, and many others. Because pea starch is similar to a gelatin in consistency, it’s very effective as a binding agent for other ingredients. Pea protein provides high protein content and added flavor. The benefits of peas don’t stop there.

Click here to determine which of Rotex Group’s food application machines is right for you.

Pea starches and proteins are byproducts of peas, which are legumes. Legumes absorb nitrogen gas from the air and store the nutrients in their roots, which reduces the demand for nitrogen-based fertilizer. Peas also require less water to grow compared with wheat, soy, and corn, yet they generate roughly the same amount of protein and nutrients.6 The sustainability and nutritional benefits of peas make them a viable ingredient for a wide range of products; however, pea starch requires careful sifting and screening to produce a safe and optimized final product. This is where Rotex Group can be a solutions provider for its customers.

Rotex Group industrial screeners have gentle action, sanitary designs, and precision control for high volume applications, providing vital sifting and separating actions across a wide range of applications. In the production of pea starch, these screeners perform the critical function of removing oversized particles or foreign materials from the final product, which helps our customers protect the health and safety of consumers. With the help of Rotex Group screeners, companies developing these vital plant-based proteins can safely and efficiently develop pea starch into a sustainable and nutritious ingredient.

Click here to ask Rotex Group a question about sanitary food separation and production capabilities.

Hillenbrand’s commitment to supporting the plant-based protein industry doesn’t stop with Rotex Group screeners. Both Rotex Group and Coperion support production operations for dozens of other such critical plant-based ingredients as soybeans, lentils, and canola. Coperion provides precision feeders, extruders, pneumatic conveying systems and complete systems for processing plants. In addition, both Rotex Group and Coperion are investing in R&D to develop next generation equipment solutions for a variety of other proteins.

Click here to download Rotex Group’s soybeans application specifications PDF.

Whether you eat meat every day, occasionally, or are vegetarian or vegan, there’s always room for nutritious plant-based protein on your plate.

1 Future Protein Supply and Demand: Strategies and Factors Influencing a Sustainable Equilibrium

2 Food and Agriculture Organization of the United Nations Key Facts and Findings

3 Plant Protein and Plant-Based Meat Alternatives: Consumer and Nutrition Professional Attitudes and Perceptions

4 Association of changes in red meat consumption with total and cause specific mortality among US women and men: two prospective cohort studies

5 Food Insight: Are plant-based proteins healthier?

6 The Rise of the Pea: How an Unassuming Legume Emerged as a Frontrunner in the Race to Replace Meat and Dairy